Metal Cutting Fluid Dipslides (Box of 10) | MCBTM2

|

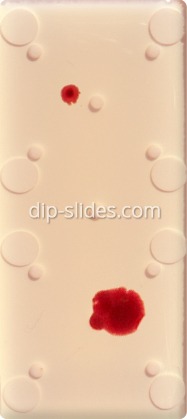

INCLUDES TTC RED SPOT DYE |

Metal Cutting Fluid Dipslides (MCBTM2™) used to comply with weekly HSE testing regulations.

For use with the Metal Cutting test kit and the Premium metal cutting test kit.

|

. UK Mainland only. (View Details). |

|

Save £1.96 per box when you subscribe to regular deliveries of MCBTM2 dipslides. Click here for details. |

|

Current stock level : 1405 |

|

Current Stock expiry date : |

|

Reward Points |

| Volume Discounts | ||

|---|---|---|

| Order 25 or more | Receive a 2.5% discount | Price £13.59 |

| Order 50 or more | Receive a 5.27% discount | Price £13.21 |

| Order 100 or more | Receive a 8.92% discount | Price £12.70 |

| Order 250 or more | Receive a 14.24% discount | Price £11.95 |

| Order 500 or more | Receive a 18.89% discount | Price £11.31 |

| Order 1000 or more | Receive a 21.5% discount | Price £10.94 |

| Product Information | ||

|---|---|---|

| Front Agar Type | Nutrient TTC (MWF Formulation) | |

| Front Agar Colour | Straw | |

| Front Agar Growth | Total Count (TTC / Red Spot) | |

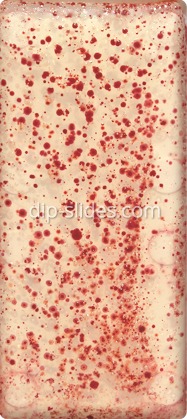

| Rear Agar Type | Malt Extract (MWF Formulation) | |

| Rear Agar Colour | Brown | |

| Rear Agar Growth | Yeasts & Moulds | |

| Certification | ISO 9001 | |

| Suggested Incubation Times | 24 - 120 Hours | |

| Suggested Incubation Temp | 30°C | |

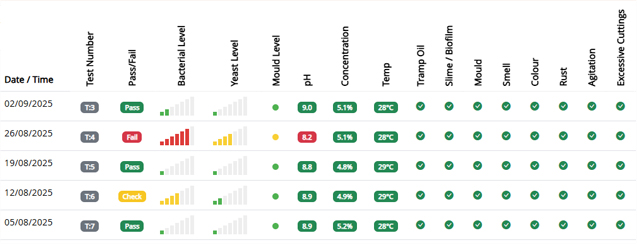

Purchasing this product offers free access to MWFLogger.co.uk - an online service allowing you to log your MW5 results to comply with HSE. Streamline your HSE compliance by recording your pH, bacterial, temperature and concentration levels in seconds. View historical data and generate pass/fail printable reports for HSE inspectors on demand with 1 click.

About Our Metal Cutting Fluid Dipslides (Box of 10) | MCBTM2

Reviews (independently collected by reviews.co.uk)

Verified Customer

Verified CustomerWednesbury, GB

Meets requirements and they will be used to test our metal working fluids within machinery

Reviewed on 09/06/2025

Verified Customer

Verified CustomerNorthampton, GB

very good and easy to use

Reviewed on 09/06/2025

Verified Customer

Verified CustomerLondon, United Kingdom

VERY GOOD

Reviewed on 24/03/2025

Verified Customer

Verified CustomerEnfield Town, United Kingdom

Quck deliver as usual

Reviewed on 17/03/2025

Verified Customer

Verified CustomerUnited States

Product ideal for my company's needs.

Reviewed on 10/03/2025

Verified Customer

Verified CustomerEdenbridge, United Kingdom

This product meets our requirements 100%, giving us the results required to abide by our legal responsibilty.

Reviewed on 04/03/2025

Verified Customer

Verified CustomerFalkirk, United Kingdom

Good product

Reviewed on 03/03/2025

Verified Customer

Verified CustomerEnfield Town, United Kingdom

great product and on time delivery

Reviewed on 07/02/2025

Verified Customer

Verified CustomerBuckley, United Kingdom

Ideal for the requirements we have.

Reviewed on 25/01/2025

Verified Customer

Verified CustomerArrived in a timely manner and has everything neatly packed

Reviewed on 20/01/2025

Verified Customer

Verified CustomerCheltenham, United Kingdom

Excellent Product

Reviewed on 08/10/2024

Verified Customer

Verified CustomerElstree, United Kingdom

Yes Product is used to gauge bacteria levels in coolant

Reviewed on 30/09/2024

Verified Customer

Verified CustomerFleet, United Kingdom

Easy to use, keeps us right for the HSE

Reviewed on 25/09/2024

Verified Customer

Verified CustomerUnited Kingdom

Not used yet

Reviewed on 24/09/2024

Verified Customer

Verified CustomerBelper, United Kingdom

It does what it says on the tin. No complaints

Reviewed on 10/09/2024

Verified Customer

Verified CustomerRoehampton, United Kingdom

The product does meet our requirements. We use these to monitor the quality of our cutting fluids in our lathe and bandsaw. The dip-slides are used in an incubator purchased also from dip-slides.com. We have never had an issue withem and they are very good.

Reviewed on 09/09/2024

Verified Customer

Verified CustomerBargain parachute anyone..? Me neither. Dipslides consistently high standards are the foundation of our confidence in our process.

Reviewed on 01/09/2024

Verified Customer

Verified CustomerGood prompt delivery

Reviewed on 15/08/2024

Verified Customer

Verified CustomerProduct gives the results we need for record keeping purposes, and enables us to take prompt action if additives are needed for the Metal cutting fluids.

Reviewed on 29/07/2024

Verified Customer

Verified CustomerUnited Kingdom

meets our needs will be used by numerous people

Reviewed on 08/07/2024

Verified Customer

Verified CustomerMilnthorpe, United Kingdom

Good value

Reviewed on 01/07/2024

Verified Customer

Verified CustomerItaly

Fast delivery as always. Easy to order, no problems. Recently had cause to speak to the Technical Team and they couldn't have been more helpful. Highly recmmend

Reviewed on 28/06/2024

Verified Customer

Verified CustomerUnited Kingdom

After a visit from HSE it was identified that we were not adequately monitoring or recording fungal and bacterial growth adequately, spoke to sales at DipSlides this kit was recommended, we now have control of both fungus and bacteria along with method of control and history in case of another visit. I'm a very satisfied customer and happy to recommend DipSlides.

Reviewed on 25/06/2024

Verified Customer

Verified CustomerUnited Kingdom

The metal cutting fluid dip slides meet all our requirements in recording our tests, covering both required tests in one easy to use tube. Each kit contains more than enough labels to cover tests for each of our machines.

Reviewed on 10/06/2024

Verified Customer

Verified CustomerNetherlands

Used to dip test machine fluids. No issues.

Reviewed on 10/06/2024

Verified Customer

Verified CustomerJerusalem, Israel

great product ewasy to follow

Reviewed on 03/06/2024

Verified Customer

Verified CustomerItaly

Product works well and accurately, never had any problems. Used to test the MWF in our CNC Machines

Reviewed on 24/05/2024

Verified Customer

Verified CustomerLondon, United Kingdom

yes thank you!

Reviewed on 20/05/2024

Verified Customer

Verified CustomerProduct shall be used to monitor bacteria/mould levels in the metal cutting fluid Reservoirs and are an ideal like-for-like of the slides we used previously. Perfect.

Reviewed on 13/05/2024

Verified Customer

Verified CustomerReigate, United Kingdom

They do what they are bought for.

Reviewed on 13/05/2024

Verified Customer

Verified CustomerUnited Kingdom

Very good indeed.

Reviewed on 13/05/2024

Verified Customer

Verified CustomerHolborn, United Kingdom

Yes, used in a CNC Machine Shop to test cutting fluid.

Reviewed on 30/04/2024

Verified Customer

Verified CustomerNotting Hill Gate, United Kingdom

The only feedback I would give is the amount in a box and the expiry dates. We are a small business and do not need the amount that is in a box......therefore there is always going to be waste product, which is not value for money or good for the environment. It would be good if a bespoke scheduled ordering service could be available. I realise you offer this for regular size boxes - but a smaller option would be ideal for our small business, who just have to periodically test our 1 machine. Thank you for asking for the feedback.

Reviewed on 29/04/2024

Verified Customer

Verified CustomerUnited Kingdom

Covers all the necessary requirements needed by the company

Reviewed on 29/04/2024

Verified Customer

Verified CustomerThese are to be used for checking bacteria level in our Machine Tools.

Reviewed on 16/04/2024

Verified Customer

Verified CustomerDerby, United Kingdom

Metaalworking fluid testing

Reviewed on 19/03/2024

Verified Customer

Verified CustomerLondon, United Kingdom

meets requirements and will be used weekly

Reviewed on 18/03/2024

Verified Customer

Verified CustomerGirvan, United Kingdom

Good quality product which is straightforward to use. Will definately be ordering from here again.

Reviewed on 18/03/2024

Verified Customer

Verified CustomerUnited Kingdom

Great price and perfect for our needs. Have used these for some time now and always had a great sevice.

Reviewed on 12/03/2024

Verified Customer

Verified CustomerBirmingham, United Kingdom

The dip slides will be used to test the slurry in our workshop

Reviewed on 08/03/2024

Verified Customer

Verified CustomerGateshead, United Kingdom

The product meet our requirements to carry put check on the metal cutting fluid.

Reviewed on 05/03/2024

Verified Customer

Verified CustomerWalsall, United Kingdom

Metal cutting soluble oil testing

Reviewed on 02/01/2024

Verified Customer

Verified CustomerRedditch, United Kingdom

This is a very good product, I will be using these Dip-Slides on our CNC Milling machine and also the saws and lathes we have. We need to keep on top of bacteria to meet HSE regulations.

Reviewed on 20/12/2023

Verified Customer

Verified CustomerUnited Kingdom

I havent used these yet

Reviewed on 07/11/2023

Verified Customer

Verified CustomerLeicester, United Kingdom

Meets our requirements

Reviewed on 06/11/2023

Verified Customer

Verified CustomerLeicester, United Kingdom

We have brought these dip slides for years from yourselves

Reviewed on 27/10/2023

Verified Customer

Verified CustomerUnited Kingdom

Metal cutting fluid Dip-Slides are perfect for our needs and have worked perfectly for all of our tests so far. Very happy with this product.

Reviewed on 09/10/2023

Verified Customer

Verified CustomerLincoln, United Kingdom

Exactly what is required to carry out the test. Well packaged so no broken slides

Reviewed on 29/09/2023

Verified Customer

Verified CustomerUnited Kingdom

All fine, does the job as previously used

Reviewed on 21/08/2023

Verified Customer

Verified CustomerNewbury, United Kingdom

perfect prouct easy to use

Reviewed on 14/08/2023

Verified Customer

Verified CustomerBexley, United Kingdom

They do what they are supposed to do.

Reviewed on 07/08/2023

Verified Customer

Verified CustomerNewbury, United Kingdom

The product meets the required needs of the company and they will be used to measure legionella in our machines.

Reviewed on 31/07/2023

Verified Customer

Verified CustomerWorcester, United Kingdom

to test saws cutting fluid to make sure it is safe to use

Reviewed on 10/07/2023

Verified Customer

Verified CustomerEasy to use just follow the instructions

Reviewed on 12/04/2023

Verified Customer

Verified CustomerWembley, United Kingdom

easy to use fit for purpose.

Reviewed on 11/04/2023

Verified Customer

Verified CustomerKensington, United Kingdom

Used for checking our Soluble Oil coolant. Delivery was prompt and order process painless

Reviewed on 03/04/2023

Verified Customer

Verified CustomerLondon, United Kingdom

Easy to use to check our cutting fluid quality. Does what we want for our weekly checks on cutting fluids.

Reviewed on 24/03/2023

Verified Customer

Verified Customermeets our requirements, used for testing metal working fluids

Reviewed on 17/03/2023

Verified Customer

Verified CustomerExcellent Product

Reviewed on 13/01/2023

Verified Customer

Verified CustomerUnited Kingdom

Excellent service. Thank you :-)

Reviewed on 09/01/2023

Verified Customer

Verified CustomerEpping, United Kingdom

work as intended

Reviewed on 19/12/2022

Verified Customer

Verified CustomerWoodford Green, United Kingdom

good and easy to use

Reviewed on 14/12/2022

Verified Customer

Verified CustomerLeicester, United Kingdom

Does what it says on the tin

Reviewed on 21/11/2022

Verified Customer

Verified CustomerBridgwater, United Kingdom

Quick and east to use

Reviewed on 13/11/2022

Verified Customer

Verified CustomerRickmansworth, United Kingdom

They do their job.

Reviewed on 07/11/2022

Verified Customer

Verified CustomerParis, France

Very fast delivery, excellent service.

Reviewed on 18/10/2022

Verified Customer

Verified CustomerEasy to use, just got to remember to store them somewhere cool

Reviewed on 18/10/2022

Verified Customer

Verified CustomerUnited States

Work well. Does what it says on the box.

Reviewed on 17/10/2022

Verified Customer

Verified CustomerWatford, United Kingdom

All received in good condition

Reviewed on 04/10/2022

Verified Customer

Verified CustomerLightwater, United Kingdom

Early days and new to testing, will feed back at a later stage.

Reviewed on 14/09/2022

Verified Customer

Verified CustomerUnited Kingdom

Does what it says on the tin.

Reviewed on 22/08/2022

Verified Customer

Verified CustomerWork as intended.

Reviewed on 19/08/2022

Verified Customer

Verified CustomerEdinburgh, United Kingdom

perfect for what we need.

Reviewed on 16/08/2022

Verified Customer

Verified CustomerLondon, United Kingdom

easy to use

Reviewed on 29/07/2022

Verified Customer

Verified CustomerEpping, United Kingdom

Easy to use as expected

Reviewed on 22/07/2022

Verified Customer

Verified CustomerUnited Kingdom

Easy to use -

Reviewed on 18/07/2022

Verified Customer

Verified CustomerEnfield Town, United Kingdom

Great product easy to use. this was a refill for the kit that we purchased previously.

Reviewed on 20/06/2022

Verified Customer

Verified CustomerUnited Kingdom

Very quick delivery kept updated all the way through

Reviewed on 31/05/2022

Verified Customer

Verified CustomerRugby, United Kingdom

The product is as described and does what we need it to do.

Reviewed on 24/05/2022

Verified Customer

Verified CustomerEpping, United Kingdom

Excellent dip slides and excellent delivery service!

Reviewed on 24/05/2022

Verified Customer

Verified CustomerCowfold, United Kingdom

quick delivery

Reviewed on 23/05/2022

Verified Customer

Verified CustomerLondon, United Kingdom

Makes monitoring coolant sumps for bacteria / mould nice and easy. Piece of mind for the saw operators & keeps us compliant with HSE guidance. Items always delivered promptly & well packed.

Reviewed on 17/05/2022

Verified Customer

Verified CustomerUnited Kingdom

Arrived quickly as always - No issues

Reviewed on 26/04/2022

Verified Customer

Verified CustomerWalsall, United Kingdom

Excellent service once again

Reviewed on 23/04/2022

Verified Customer

Verified CustomerAndover, United Kingdom

Sorry about reporting them as not delivered - we found them

Reviewed on 16/03/2022

Verified Customer

Verified Customer", United Kingdom"

consistent results, easy to use

Reviewed on 14/03/2022

Verified Customer

Verified CustomerUnited Kingdom

Prompt delivery with a great all-round service.

Reviewed on 15/02/2022

Verified Customer

Verified CustomerLeicester, United Kingdom

Easy to use

Reviewed on 23/09/2021

Verified Customer

Verified CustomerCardiff, United Kingdom

Everything you need and simple to use!

Reviewed on 23/09/2021

Verified Customer

Verified CustomerUnited Kingdom

Good quality, do what they should. Great

Reviewed on 20/09/2021

Verified Customer

Verified CustomerPoplar, United Kingdom

Simple and easy to use. A convenient way to monitor coolant quality and to help ensure our compliance with the health and safety regulations.

Reviewed on 20/09/2021

Verified Customer

Verified CustomerLondon, United Kingdom

All good and easy to use.

Reviewed on 02/09/2021

Verified Customer

Verified CustomerLondon, United Kingdom

VERY GOOD

Reviewed on 01/09/2021

Verified Customer

Verified CustomerUnited Kingdom

Kits work very well and will be ordering again

Reviewed on 27/08/2021

Verified Customer

Verified CustomerHarrow, United Kingdom

Easy to order and next day delivery, great service.

Reviewed on 25/08/2021

Verified Customer

Verified CustomerThornton, United Kingdom

Everything was in the box as required.

Reviewed on 23/08/2021

Verified Customer

Verified CustomerUnited Kingdom

Good quality

Reviewed on 16/08/2021

Verified Customer

Verified CustomerUnited Kingdom

Good quality

Reviewed on 16/08/2021

Verified Customer

Verified CustomerUnited Kingdom

Good quality

Reviewed on 16/08/2021

Verified Customer

Verified CustomerNewbury, United Kingdom

perfect for our H&S needs....

Reviewed on 16/08/2021

Verified Customer

Verified CustomerUnited Kingdom

Arrived on time, as described

Reviewed on 06/08/2021

Verified Customer

Verified CustomerNewbury, United Kingdom

Perfect for our health and safety needs...

Reviewed on 29/06/2021

Verified Customer

Verified CustomerGoole, United Kingdom

Will use again

Reviewed on 26/05/2021

Verified Customer

Verified CustomerMansfield, United Kingdom

Great products and service

Reviewed on 18/05/2021

Verified Customer

Verified CustomerPoplar, United Kingdom

Only just started with the first test batch but they seem easy and hygienic to use.

Reviewed on 12/05/2021

Verified Customer

Verified CustomerPontefract, United Kingdom

5* Good shelf life

Reviewed on 06/05/2021

Verified Customer

Verified CustomerUnited Kingdom

Easy to use. Exactly what is needed to monitor quality of metal cutting fluids & ensure compliance with HSE requirements.

Reviewed on 29/04/2021

Verified Customer

Verified CustomerWembley, United Kingdom

seem good and simple to use, we are about to start the process shortly.

Reviewed on 19/04/2021

Verified Customer

Verified CustomerEnfield Town, United Kingdom

To use a cliche.....it does what it says on the tin!

Reviewed on 31/03/2021

Verified Customer

Verified CustomerTolkamer, Netherlands

Just what we needed for the testing and easy to use

Reviewed on 25/03/2021

Verified Customer

Verified CustomerUnited Kingdom

The dip-slides performed as per the literature provided 48 hours after delivery we had our test results and were able to carry out any corrective actions required.

Reviewed on 01/03/2021

Verified Customer

Verified CustomerWorcester, United Kingdom

easy to use

Reviewed on 01/03/2021

Verified Customer

Verified CustomerInverness, United Kingdom

Compact and easy to use and to read results.

Reviewed on 24/02/2021

Verified Customer

Verified CustomerLondon, United Kingdom

Arrived on time.

Reviewed on 23/02/2021

Verified Customer

Verified CustomerSimple to use, worked very effectively.

Reviewed on 25/09/2020

Verified Customer

Verified CustomerEasy to use, clear instructions

Reviewed on 05/08/2020

Verified Customer

Verified CustomerGreat Product

Reviewed on 21/07/2020

Verified Customer

Verified Customervery good product and at a competitive price compared to other companies.

Reviewed on 17/07/2020

Verified Customer

Verified CustomerEasy to use

Reviewed on 16/07/2020

Verified Customer

Verified CustomerThese are better value than the ones we were buying before and do an excellent job. Fast efficient service!

Reviewed on 09/07/2020

Verified Customer

Verified CustomerEasy to use with good instructions on how to check metal cutting fluids

Reviewed on 29/06/2020

Verified Customer

Verified CustomerVery reliable and easy to use.

Reviewed on 29/05/2020

Verified Customer

Verified CustomerThey do what they say on the tin!

Reviewed on 20/05/2020

Verified Customer

Verified CustomerGood to use and makes the job of checking coolant very easy.

Reviewed on 25/02/2020

Verified Customer

Verified CustomerNever had any issues with these at all

Reviewed on 25/02/2020

Verified Customer

Verified CustomerDoes the job that I needed them for

Reviewed on 05/02/2020

Verified Customer

Verified CustomerReviewed on 24/01/2020

Verified Customer

Verified CustomerThey do the job, and keep the HSE happy!

Reviewed on 23/01/2020

Verified Customer

Verified CustomerGood quality, great price

Reviewed on 16/01/2020

Verified Customer

Verified CustomerIt is reassuring to find a full range of dip-slides for the analysis of individual situations that we have. Technical guidance has proven to be beneficial.

Reviewed on 02/01/2020

Verified Customer

Verified CustomerThese kind of dip slide is exactly the kind of thing the HSE likes to see, they come with a record chart and are easy to read

Reviewed on 19/12/2019

Verified Customer

Verified CustomerThe metal fluid dipslides were easy to use.

Reviewed on 13/12/2019

Verified Customer

Verified CustomerEasy to use, instructions/result table straightforward - would recommend

Reviewed on 04/12/2019

Verified Customer

Verified CustomerThe dipslides are simple to use and interpret. It makes monitoring the cutting fluid a simple quick process which requires no specific training.

Reviewed on 26/11/2019

Verified Customer

Verified Customerperfect...

Reviewed on 19/11/2019

Verified Customer

Verified CustomerDoes exactly what I want!

Reviewed on 14/11/2019

Verified Customer

Verified CustomerExactly what we needed, following our h&s review.

Reviewed on 01/11/2019

Verified Customer

Verified CustomerEasy to use and quality just perfect for our application!

Reviewed on 18/10/2019

Verified Customer

Verified CustomerEasy to use & a fast dispatch

Reviewed on 01/10/2019

Verified Customer

Verified CustomerThe Dip-Slides themselves are simple to use with clear instructions included in the package as well a simple clear instructions on how to interpret the results. I would recommend this to anyone looking for a simple effective way of monitoring your metal cutting fluid

Reviewed on 24/09/2019

Verified Customer

Verified CustomerReviewed on 20/09/2019

Verified Customer

Verified CustomerReviewed on 21/08/2019